Lean Duplex according to NORSOK M-120 MDS YD35 has an improved balanced chemistry of chromium, molybdenum and nitrogen content, resulting in a PRE value ≥ 28 and increased mechanical strength compared to the standard EN 1.4362 / UNS 32304. This grade outruns AISI 316L acc. to both EN 1.4404 & EN 1.4436 with respect to pitting corrosion resistance. Due to risk of embrittlement, duplex steels should not be used at temperatures above 250 – 325°C.

Trademark information: EDX 2304 is a trademark owned by Outokumpu OY.

EN 1.4362 / Lean Duplex UNS S32304 / EDX 2304 is characterized by:

- Good resistance to stress corrosion cracking.

- Good resistance to pitting and crevice corrosion.

- High resistance to general corrosion.

- High mechanical strength.

- High resistance to erosion corrosion and corrosion fatigue.

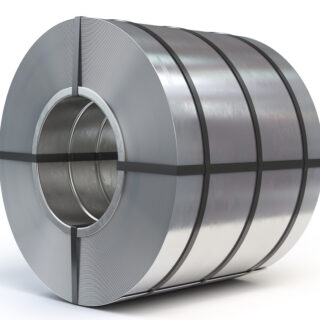

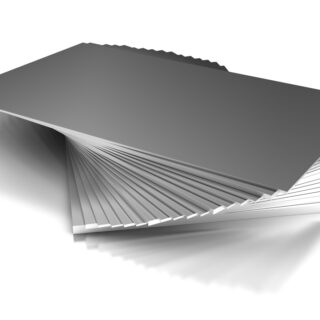

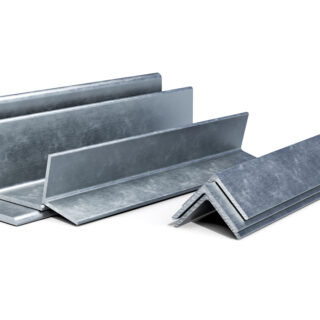

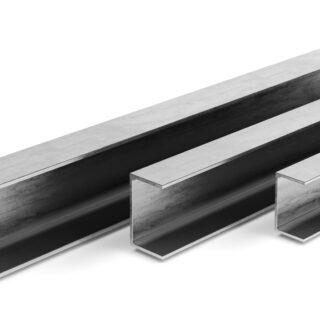

We stock EN 1.4362 / Lean Duplex UNS S32304 / EDX 2304 in the following products:

- Coil

- Plate

- Hollow Section

- Angle Bar – Hot Rolled

- Angle Bar – Laser Welded

- H-beam

- Flat Bar – Laser Cut from Plate

- U-profile – Laser Welded

See the dimensions below.

-

Applications

-

Heat Tratment and Weldability

-

Chemical Composition (Specific for Plates)

-

Reference Standards

-

Mechanical Properties (Typical)