Duplex 1.4460 / AISI 329 in Stock

We have expanded our comprehensive program to include 1.4460 / AISI 329 in solid round bars.

We have expanded our comprehensive program to include 1.4460 / AISI 329 in solid round bars.

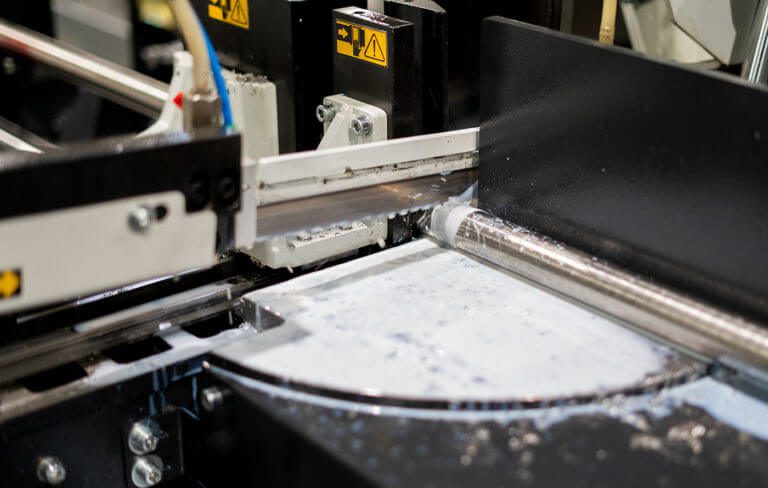

Duplex 1.4460 / AISI 329 is especially suited for the manufacture of components for pumps and other equipment used in, for example, alkaline environments commonly found in the pulp and paper industry. This grade has good weldability, machineability and formability.

We stock a complete range from OD 27 mm up to include 184 mm. See the full 1.4460 / AISI 329 stock program here.

With it’s two-phased microstructure of equal amounts of austenite and ferrite, Duplex stainless steel is the preferred choice for applications such as storage tanks, pressure vessels, heat exchangers, bridges, railings, aquaculture, desalination systems, and various other uses. In addition, its renowned strength, corrosion resistance, and low maintenance makes Duplex a cost-effective and reliable alternative to standard austenitic stainless steels, such as 304 and 316L. Especially in offshore or coastal locations.

Utilizing the strength of Duplex compared to carbon steel and ordinary stainless steel means less cost due to weight savings by reducing the thickness. It also requires less handling, fabrication, and welding. In addition, duplex stainless steel is known for improved balanced chemistry of chromium, molybdenum, and nitrogen, allowing less nickel content, consequently leading to better price stability over time. These are just a few reasons why Duplex material outperforms the more traditional stainless steels.

Construction, petrochemical industry, paper production or offshore oil platform – regardless of what you will build, enforce or repair, we at Sverdrup Steel can provide you with Duplex material of the highest quality – in the shape and quantity you like.

At Sverdrup Steel, you can choose from a wide range of Duplex stainless steel with different duplex grades and alloys. We offer a wide variety of austenitic-ferritic steel for all purposes and industries. Choose between Lean Duplex, Standard Duplex and Super Duplex alloys. Depending on your project, you may need to pick a duplex steel with the right PREN (pitting resistance equivalence number). Feel free to use our digital PREN calculator to identify the accurate duplex grade for your project.

Compared to standard Duplex, Lean Duplex is a fairly new invention. The primary use for this duplex grade is building and construction, where the need for super-high corrosion resistance isn’t as high as in other industries. Although, it still possesses all the other qualities of duplex steel, such as higher strengths, lower weight and fewer maintenance requirements (compared to austenitic alloys). When it comes to lean duplex steel, we can offer three different alloys, each with its specific qualities.

SS LD24 / UNS S32001 is a low alloyed Lean Duplex stainless steel with a PREN of ≥24, thanks to increased Cr, Mo and N content. With a 50/50 phase balance of ferrite and austenite, this lean Duplex stainless steel grade provides much higher yield strength than ordinary austenitic steel. Also, it exhibits good formability and corrosion resistance.

LDX 2101 / UNS S32101 is a low Ni-alloyed duplex with balanced chemical composition of Ch, Mo and Ni, which gives the steel a good resistance to localized and uniform corrosion, in combination with excellent weldability. Thanks to its price stability and high strength, it’s an ideal choice for a wide range of industries and purposes.

EDX 2304 / UNS S32304 has an improved balanced composition of Ch, Mo and Ni, resulting in a PREN of ≥ 28 and increased mechanical strength compared to the standard UNS 32304. If you are looking for a lean duplex with unmatched resistance to pitting corrosion, then UNS S32304 is the best choice.

The process of mixing ferritic and austenitic to make super-strong and corrosion-resistant Duplex steel is almost 100 hundred years old. However, thanks to modern technology and methods, we can now produce duplex stainless steel of higher quality with lower climate impact, using up to 85 % recycled steel.

Duplex UNS S31803 / S32205 are the most common duplex grades in the market today. They are known for their excellent resistance to localized corrosion and stress corrosion cracking. In addition, they have very high mechanical strength and weldability. Standard duplex stainless steels are widely used in oil, gas and paper production industries and are ideal for hydropower, pressure vessels, structural components and chemical tankers. Standard Duplex is the perfect choice when you don’t want to choose between high strength and high corrosion resistance.

Super Duplex is a special type of duplex stainless steel developed to meet the extremely high standards from oil, gas and chemical industries. With Super Duplex you will have a heavy duty stainless steel made especially for aggressive chloride-rich and halide environments, making it the duplex grade of choice for everything from pressure vessels and chemical tankers to paper and pulp equipment.

Super Duplex UNS S32750 and UNS S32760 are two of the most frequently used super duplex grades in the world. They have very good resistance to localized corrosion and stress corrosion cracking, in addition to high mechanical strength. In contrast to UNS S32750, UNS S32760 also contains amounts of Wolfram and Copper, for increased heat resistance.

Although Duplex steel is known to be easily weldable and processed, it’s always nice to avoid unnecessary work. By choosing Sverdrup, you can order Duplex steel products based on shape and size. Explore our duplex coils and bars in different widths and lengths, or order a custom-sized duplex plate or steel profile ready for delivery.

If you have any questions or enquiries, please contact us.

Published: 12 Dec 23

News